Riding the Gray Wave: How Ergonomics Can Help You Master Workplace Safety for Older Workers

The demographics of humanity are evolving, and our species is growing older.

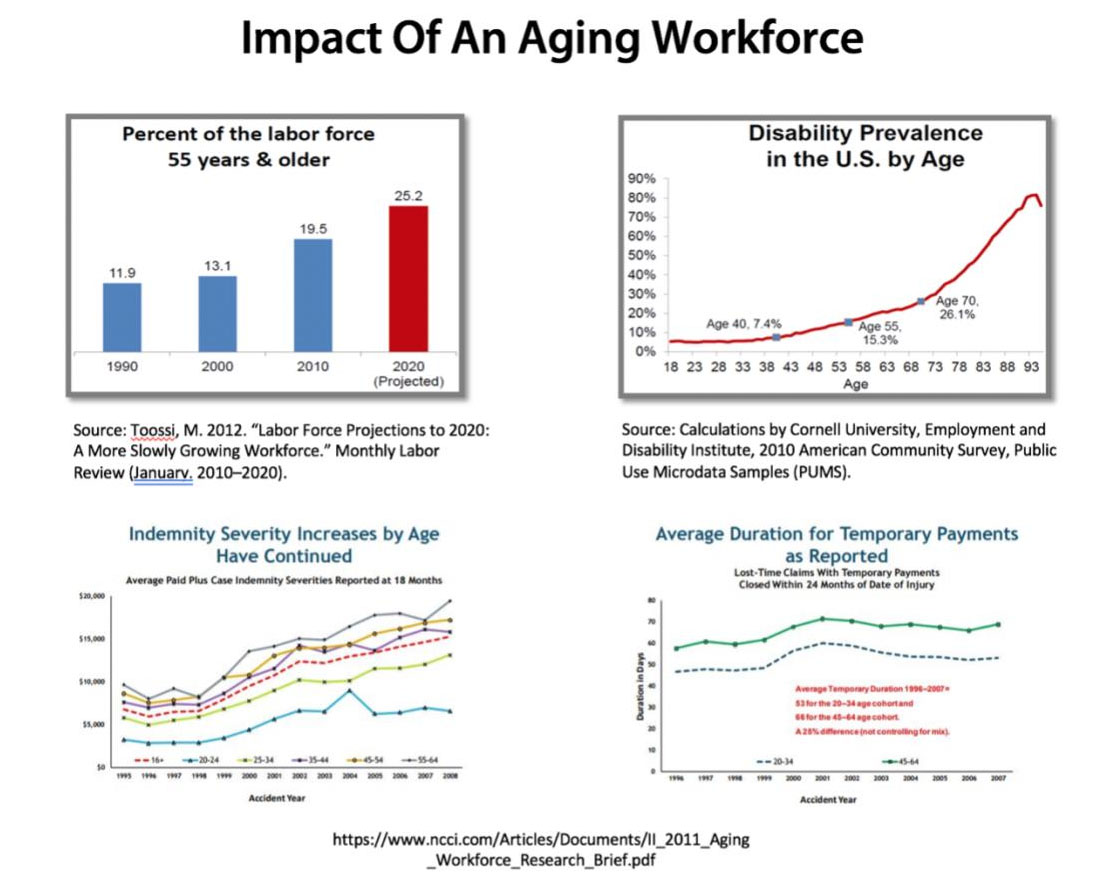

In 2015, a report by the United Nations projected that one in three people in the “developed world” will be aged over 60 by 2050, a shift that will have profound implications for the global workforce: Not only high levels of valuable real-world experience, but also greater injury and fatality risks, more missed work days and an uptick in the seriousness of work-related injuries.

In the United States, roughly 25% of the labor force is over 55 years old, and with economic conditions fluctuating as a result of the COVID-19 pandemic, it’s now less likely than ever that Baby Boomers will retire at 65.

And we’re not just talking about low-impact jobs — the average highly skilled manufacturing worker is 56 years old, so it’s clear that key portions of the global economy rely on more experienced employees.

The “gray wave” has arrived, and enterprises need to adapt proactive ergonomic solutions to protect older workers.

Rather than fearing the change, wise businesses will recognize this opportunity to support older workers whose experience and unique skill set will become more valuable as the economy reopens.

Common Risks for Older Workers

Research is still defining the primary injury risks for this sector of the workforce, but what is available does paint a useful picture.

A few descriptors stand out.

Older workers demonstrate decreased strength, balance and flexibility and experience reductions in sensory perception and manual dexterity. Older bodies absorb less oxygen and experience fatigue more quickly. Even psychosocial factors such as learning style and company culture introduce risks for older workers.

Often, these factors manifest themselves in the form of pain. Musculoskeletal pain is a major productivity and morale inhibitor, and the economic impact of pain can reach well over $1 trillion per year between direct costs, presenteeism and potential misuse of prescription medication.

* Darrell J. Gaskin, Patrick Richard. The Economic Costs of Pain in the United States. The Journal of Pain, 2012; 13(8)

** Global Corporate Challenge – GCC Insight Report March 2016 http://ehstoday.com/safety-leadership/presenteeism-costs-business-10-times-more-absenteeism

*** FiercePharma.com – Palmer, E. (2016). Employers tackling costs of opioid abuse with testing, alternative treatments. CDC http://www.fiercepharma.com/pharma/employers-tackling-costs-opioid-abuse-testing-alternative-treatments

**** The Burden of Musculoskeletal Diseases in the United States: Prevalence, Societal, and Economic Costs

***** National Safety Council https://www.nsc.org/work-safety/safety-topics/fatigue/calculator/cost

Older workers are also more likely to suffer fractures and dislocations at work than younger employees, with the risk more than doubling for women over 55.

More, a study by the Institute for Work and Health determined that time off work after an injury increases with age.

Preexisting conditions among older workers partly explains the disparity; the rest comes down to a mix of factors, including the availability of preventative care and safety training. That’s where ergonomics come into play.

Understanding the Role of Ergonomics

Applying ergonomics to an aging workforce requires a nuanced understanding of the work environment, task design and the traits of older workers.

Various services offer workplace monitoring and health analysis, from wearable devices to on-site coaching in proper body mechanics, general mobility and pre-shift conditioning by contracted safety specialists.

Evaluation begins with analysis of individual traits, workstations and equipment before zooming out to the departmental and organizational level.

With that data, ergonomics specialists can properly analyze the workplace and craft effective solutions.

Ergonomic Interventions: Preventing Injuries to Older Employees

Thanks to the COVID-19 pandemic, ergonomists are likely to be kept busy in the coming months as companies seek solutions for the rising wave of injury risks, which without intervention promises a cost spike of equal proportion.

While each business will tailor its response to its specific operational challenges, ergonomic solutions tend to fall into one of two categories: administrative and engineering controls.

For example, ergonomics-focused training falls under the banner of administrative controls — solutions that involve changing company policies toward better ergonomic practices.

Even in this age of burgeoning work-from-home policies, training remains an essential part of any safety strategy. Programming should include ergonomic best practices catered to the needs of older workers, especially around high-risk motions like pushing, pulling, bending and lifting.

Other administrative controls include job rotation, shift changes, fatigue identification systems, conditioning programs, wearable technologies and a robust pain management program.

Engineering controls focus on making concrete changes to workstations, tools or other physical aspects of the workplace.

An ergonomic assessment performed with older workers in mind will reveal opportunities to redesign workspaces and tools to better suit their needs.

Up-to-date equipment and modernized workstations allow more flexibility and offer greater support with posture and body mechanics. Since older workers are also more likely to experience work-related chronic pain, many organizations also prioritize therapies that target ergonomic factors.

A few companies have managed to leap ahead of the curve when it comes to using ergonomics to reduce injuries to long-tenured workers. One in particular stands out for its foresight.

Ergonomics in Action: Case Study from a Major Airline

Few industries are as labor-intensive as the air travel business, so the way a major airline tackled its aging workforce and growing injury risks in 2019 is quite instructive.

After one company experienced rising injury rates as its average worker grew older, it began strategizing ways to protect employees responsible for baggage handling, managing ticket counters and other high-impact tasks.

Ergonomic assessments showed older workers struggled with poor flexibility and pain concentrated in the shoulders, back and neck.

The solution? A tailored program of on-site pain-relief therapy targeting soft-tissue strain, mobility and conditioning training, and a slate of ergonomic improvements.

Specialists discovered hazards both on the tarmac and inside airports, which they addressed by recommending redesigned tools and workstations as well as additional body mechanics training. Potentially harmful employee behaviors were identified and retaught, with special training to help older workers overcome any physiological disadvantages.

After eight months, the airline reported improvements in both concrete factors and employee morale.

After a single 30-minute training session, employee range of motion increased by 75%. Learned behaviors were retained at a 96% rate even six or seven months after the initial training, becoming instinctive movements for employees.

In addition, pain levels decreased by 83%, and the rate of injuries for the areas targeted by the ergonomics program dropped to zero, resulting in savings of hundreds of thousands over this short period in one location alone.

Employees across the board responded positively to post-program surveys, with 90% reporting improved morale and 92% saying that their jobs got easier. Finally, overall productivity increased by 11%, and medication usage dropped by 22% — clear signs that ergonomics can reduce risk and cut direct costs while improving company culture.

Ergonomics as a Safety Cornerstone

With the nature of work changing rapidly as a result of COVID-19 and economic pressures for the average worker climbing, the world of workplace safety is sure to be rocked in the coming years.

The best thing safety managers can do at this point is be prepared.

With ergonomic solutions as a prominent part of the safety toolkit, though, the inevitable rise in worker age and injury risk can be transformed from catastrophe to opportunity. &