What Are Glovebox Ergonomics? The National Ergo Conference Breaks Down Its Best Practices

Each year, the National Ergonomics Conference features leading experts and exhibitors who share a wealth of knowledge about ergonomic issues as well as showcasing products and technology that help address ergonomic performance.

Prior to this year’s conference, which is scheduled to be held Nov. 2-5, 2021 in Las Vegas, various digital sessions are being held throughout the year — offering continuous education opportunities for those interested in the discipline.

On March 16, Martha Chan, an ergonomist specializing in glovebox ergonomics for Las Alamos National Laboratory, will present the session “Stuck in the Box: Challenges in Glovebox Ergonomics,” which will focus on the ergonomic challenges associated with today’s glovebox environments.

When Dealing with Big Risks, Never Forget the Small Ones

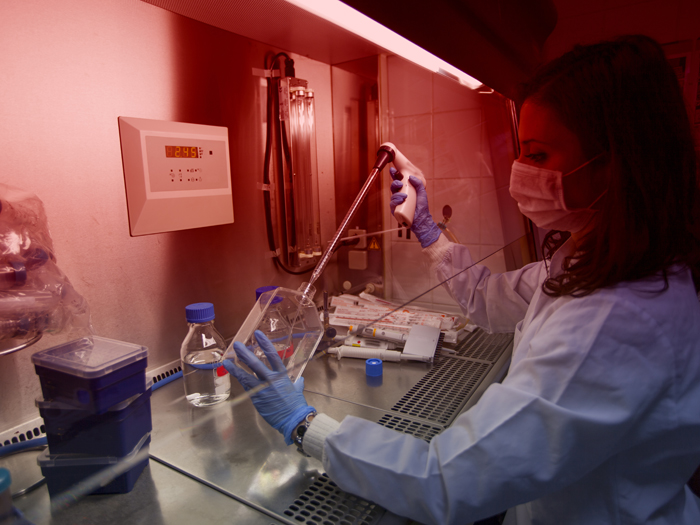

At their core, gloveboxes are containment workspaces that are designed to allow a worker to manipulate objects where a separate atmosphere is desired. As Chan explains, today’s gloveboxes present inherent ergonomic challenges as most of their physical features are non-adjustable.

As an example, the Los Alamos National Laboratory’s (LANL) Plutonium Facility has over 300 gloveboxes in use today with 400 workers performing manufacturing work inside gloveboxes for most of their work day. As a result, LANL’s ergonomics team has a specialized glovebox functional area to mitigate ergonomic risks that gloveboxes present.

“A glovebox is a containment unit with gloveports that allow the operator to handle material that requires a different atmosphere,” Chan said.

“The material could be hazardous to the operator, such as radioactive material could be, or it could be that the operator is hazardous to the material, as some nanotechnology or pharmaceuticals could be contaminated by human touch.”

Glovebox uses appear in multiple industries — from nuclear to pharmaceutical to nanotechnology. Glovebox work is inherently difficult and usually involves hazards that require containment.

“Because of these obvious hazards, like explosives or radiation, we often forget about the everyday hazards like repetitive motion injuries,” Chan said.

“Our program ergonomists have seen ergonomic injuries, mostly upper extremities, that require surgery and are even career ending. Being able to proactively look at glovebox designs and processes to prevent ergonomic issues can be key to retaining highly trained workers for the company.”

Tackling Ergonomic Issue Head On

During her upcoming webcast, Chan will explain that when the LANL glovebox ergonomics team started in 2012, they decided to take a comprehensive approach to addressing ergonomic issues at the site.

The team’s approach included assessing past incidents, seeking management support and engaging the workforce in establishing safeguards and solutions.

As Chan explained, LANL’s glovebox ergonomics team began by looking at injury and illness data that showed elevated concerns of shoulder and elbow symptoms among 400 glovebox workers.

“Through worker engagement and manager commitment, the LANL team rapidly improved glovebox work environment by collaborating with workers, other safety professionals, and upper management to address ergonomic risks associated with glovebox work,” Chan explained.

A Journey to Addressing Glovebox Concerns

Chan first became interested in glovebox ergonomics thanks in part to her mentor, Cindy Lawton.

“My academic background is in kinesiology and biomechanics, and I started with LANL in 2016,” Chan said. “I met my mentor in 2015, and she was a physical therapist and ergonomist with the lab. She saw injuries in the glovebox worker population as a physical therapist and saw the opportunity to ‘do good’ in glovebox ergonomics.”

So does Chan see the focus on glovebox ergonomics increasing in the future? Absolutely.

“Ask any graduate student in science who has worked in a glovebox, and they can tell you that glovebox work is not fun and very physically straining,” Chan said.

However graduate students are usually young and do not yet feel the effects of repetitive motion injuries. But that’s not necessarily the case in industry and manufacturing, where they are seeing the importance of ergonomics as the glovebox workforce is aging and more workers are reporting severe symptoms.

The Success of a Specialty Ergo Program

During Chan’s upcoming ergonomic presentation she hopes to engage with the audience and explain how specialty ergonomics, like gloveboxes, can easily gain traction if ergonomists can focus on the worker population and get to the nitty-gritty of the problem.

“In addition to the initial changes, worker engagement and workplace improvements are continuous,” Chan said. “The key to ensuring the success of any ergonomics hazard control efforts is to gain trust with workers who are the boots on the field.”

Even though the percentage of glovebox workers who experience ergonomic symptoms is noteworthy, it is easy for the focus to not be on them, because the number of glovebox workers are so few in comparison to the population of, say, computer workers.

“I think that certain companies may have a decent amount of glovebox workers and may have a good ergonomic program for that specialty, but it is often difficult to forge any partnership or communicate lessons learned as we are not sure where other programs like ours are located,” Chan said.

“That’s why I think discussing these topics at a forum like ErgoExpo is pertinent to the success of a specialty ergo program.”

For more information about the ongoing webcasts being offered by the National Ergonomics Conference, including Martha Chan’s upcoming webcast, visit www.ergoexpo.com. &