Construction Industry

The Cost of Compliance

Across the construction industry — from single-family homes to high-rise office towers to new highways — contractors struggle to comply with a myriad of federal, state and local regulations that are putting pressure on margins.

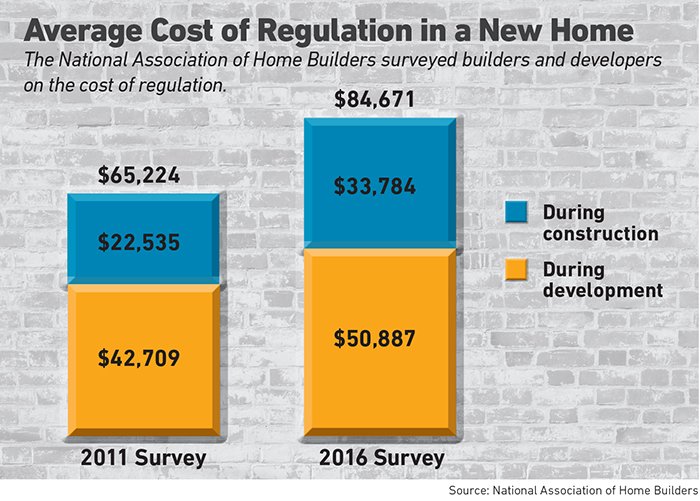

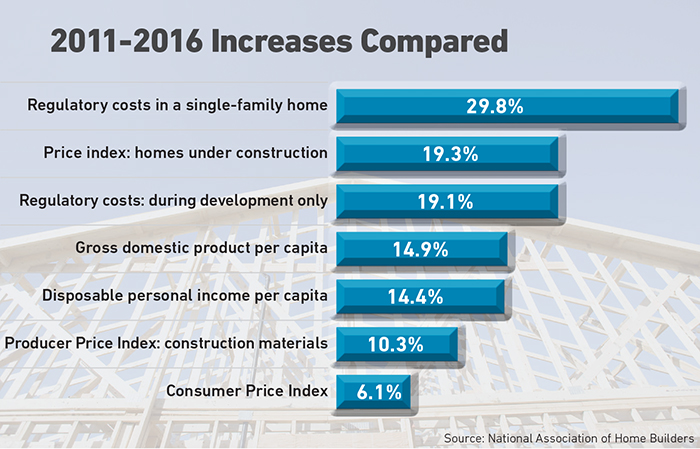

Take residential construction. On average, regulations imposed by government at all levels account for 24 percent of the final price of a new single-family home, according to the National Association of Home Builders in Washington, D.C.

Roughly 60 percent of that is due to costs during the lot development stage, including delay costs from having to seek approval or wait for government decisions, said Robert D. Dietz, the trade group’s chief economist.

“If a company has loans outstanding on particular projects, delays cause those firms to incur additional interest expense,” Dietz said.

“There are also costs for zoning and subdivision approval, as well as costs for leaving land undeveloped for green space, per government requirements.”

Regulatory costs imposed during the home construction phase include permit and hookup fees, development impact fees and costs to meet building code requirements, and costs to keep projects compliant with ever-increasing environmental regulations.

The Environmental Protection Agency and the Army Corps of Engineers are seeking to expand the types of land that require a clean water permit, which can cost tens of thousands of dollars per lot, Dietz said.

Ongoing effects of requirements associated with complying with stormwater regulations are also included in embedded costs.

As for general building requirements, typically the market demands energy-efficient windows and envelope of the house, but in some cases those requirements are being increased, which in turn increases the costs of the materials and construction, he said.

Residential contractors need to stay up-to-date on the rapidly changing application of each state’s right-to-repair statutes for owners of new homes and condominiums by courts and insurance carriers, as failure to strictly adhere to the evolving laws can greatly increase the contractor’s exposure, said Rodney Moss, senior vice president with Aon Risk Solutions’ construction services group in Dallas.

Until 2013, Moss served as in-house counsel for Balfour Beatty Construction (formerly Centex Construction).

All types of contractors also need to be up-to-date on the latest environmental regulations not only from the EPA, but also from applicable state and even local jurisdictions, such as rules on construction equipment emissions in California, Moss said.

“The regulations are becoming increasingly difficult to comply with, particularly for national contractors working in multiple states with different standards,” Moss said.

“Investigations and enforcement actions often result in the jobsite getting shut down, and there are balance sheet risks beyond just the fines because regulatory citations can also become a default under the construction contracts and often spawn expensive civil litigation from the injured parties,” he said.

Moreover, regulatory compliance has almost become a strict liability issue, as regulators are less flexible: They issue punitive citations first, and then contractors must go through an appeals process, Moss said.

“Contractors are terrified that they will be the one that the regulators try to make an example of,” he said.

‘Blacklisting Executive Order’

Jimmy Christianson, regulatory counsel at the Associated General Contractors of America, said that the trade group is concerned by a number of recent federal actions, including President Barack Obama’s 2014 Fair Pay and Safe Workplaces Executive Order, or what the AGC refers to as the “Blacklisting Executive Order.”

Per the Federal Register, the order requires federal contractors to report whether there has been an administrative merits determination, civil judgment, or arbitral award or decision rendered against them during the preceding three-year period for violations of any of 14 identified federal labor laws, executive orders or equivalent state laws.

Contracting officers and labor compliance advisers will assess whether the violations are serious, repeated, willful or pervasive, as part of the determination of whether a contractor has a satisfactory record of integrity and business ethics.

Christianson said the order is onerous because it requires prime contractors to review the labor law records of potentially hundreds of subcontractors bidding on a $50 million job, and then possibly require them to sign labor compliance agreements with federal enforcement agencies before the agencies allow the subcontractors to bid on work.

“However, there already is a suspension and debarment process so this additional step isn’t necessary — it just adds more time and paperwork to the procurement process,” he said.

“This order is really just about giving labor agencies more leverage to get down deeper into those companies, which produces more risk of blacklisting.”

The AGC is also concerned about a post-injury drug testing rule by the Occupational Safety and Health Administration set to take effect in 2017, that amends regulations pertaining to the recording and reporting of occupational injuries and illnesses, said Kevin Cannon, AGC director of safety and health services.

Per the Federal Register, while the new rule does not ban drug testing of employees, it does prohibit employers from using drug testing — or the threat of drug testing — as a form of adverse action against employees who report injuries or illnesses.

Employers should limit post-incident testing to situations in which employee drug use is likely to have contributed to the incident, and for which the drug test can accurately identify impairment caused by drug use, it said.

“OSHA views such testing as an invasion of privacy and unnecessary based on the worker’s type of injury or illness,” Cannon said. “However, we think post-incident drug testing is very important to ensure safety on the worksite — not as a stand-alone tool, but rather as part of a comprehensive safety program.”

A $5 Billion a Year Rule

Michael Halter, Northeast zone workforce strategies practice leader with Marsh Risk Consulting in Rochester, N.Y., said that OSHA’s regulations have had many positive results, including the reduction of annual workplace fatalities from 14,000 prior to the agency’s creation in 1971, to 4,821 in 2014.

Still, sometimes industries need to challenge the agency’s assertions on the cost of new regulations, Halter said.

For example, OSHA’s new rule on occupational exposure to crystalline silica significantly lowered the permissible exposure limit and provided additional worker protections. While OSHA estimated that the new rules would cost the industry $511 million per year, a study by the Construction Industry Safety Coalition concluded the change would actually cost $5 billion a year.

“We advise our construction clients on how to comply with the silica and other OSHA standards using substitution, engineering controls, work practice control, administrative controls and personal protective equipment,” Halter said. “Other control methods may include the use of prevention through design principles and pre-fabrication.”

State and local governments also have increased their regulation of employer-employee relations with increases in minimum wage, requirements for paid sick leave, options for retirement investments in the private sector and more, said E. Colette Nelson, chief advocacy officer at American Subcontractors Association Inc. in Alexandria, Va.

The trade group continues to focus its government advocacy efforts on issues that are unique to construction subcontractors, including ensuring that subcontractors have payment assurances on projects financed through public-private partnerships at both the federal and state levels; requiring federal and state government contracting entities to process and pay change orders in a timely manner; and encouraging federal and state governments to improve the transparency of their payment practices.

“This includes making the prime contractor’s payment bond more readily available to subcontractors and suppliers, such as by posting it on a website; making available information on payment to prime contractors; and by providing a report on the status of each change order on a project,” Nelson said.

Paul Becker, global industry leader, construction, at Willis Towers Watson in Nashville, Tenn., said the construction industry is grappling with medical and recreational marijuana laws state-to-state and the associated labor dilemmas.

“Since the laws are quite new, there really isn’t case law, claims history or agreed-upon levels for testing, so it’s emerging as a challenge,” Becker said.

“The industry can test employees for the drug and ban the use of it, but it’s not clear yet exactly how marijuana is going to impact an organization’s overall risk. Ultimately, marijuana will be reflected in data around worker injuries if usage increases significantly, and the industry will begin to price for it.”

Contractors also have to be cognizant of new rules by the Federal Aviation Administration concerning another emerging risk: the commercial use of drones.

Under the rules, the person actually flying a drone must have a remote pilot certificate with a small UAS rating, or be directly supervised by someone with such a certificate. Among other height, speed and operational restrictions, pilots must keep drones within visual line of sight.

The new rules should allow construction firms and their insurers to provide appropriate risk management strategies and coverage for them, Becker said.

“So in this way the new regulations are actually an example of an effective response to a new technology,” he said. &